The oil and gas industry along the Gulf Coast is a cornerstone of the region’s economy, employing thousands of workers across diverse roles and sustaining numerous coastal communities. However, a pressing issue has emerged that demands immediate attention: the direct link between inadequate equipment maintenance and the increasing incidence of workplace injuries.

As regulatory bodies like the Occupational Safety and Health Administration (OSHA) heighten their oversight, industry leaders face the critical task of harmonizing productivity goals with stringent safety requirements. This challenge is particularly acute given that equipment failures or malfunctions can lead to severe, potentially catastrophic outcomes, underscoring the vital importance of robust maintenance protocols and safety measures in this high-risk sector.

Critical Components and Maintenance Challenges

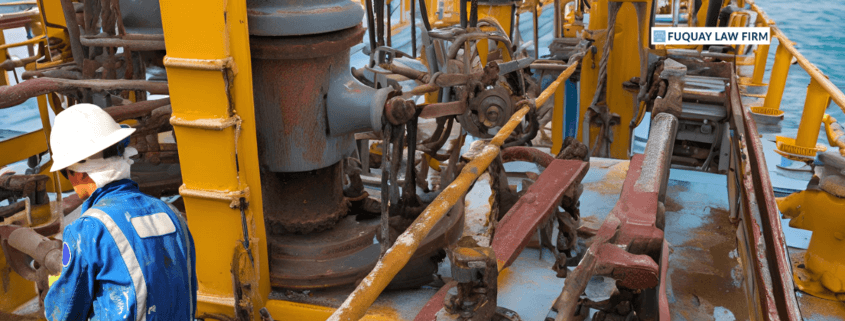

Gulf Coast drilling operations, both onshore and offshore, rely on complex machinery that requires meticulous maintenance to ensure safety and efficiency. From the towering derricks that punctuate the Alabama skyline to the massive floating rigs in the Gulf of Mexico, these structures are intricate systems of machinery working in concert. When even one component falters due to inadequate upkeep, the consequences can be severe.

Key equipment includes:

- Blowout Preventers (BOPs): These crucial safety devices prevent uncontrolled oil and gas releases. A single poorly maintained BOP on an offshore rig near Mobile could lead to a catastrophic failure, endangering not only the crew but also the delicate marine ecosystem of the Gulf.

- Drill Strings: The lifeline of any drilling operation, these components undergo extreme stress and require regular inspections to prevent breakages that could lead to serious injuries.

- Mud Pumps: Vital for circulating drilling fluid, faulty mud pumps can cause pressure imbalances, potentially leading to wellbore instability and blowouts.

- Derricks: These iconic towers must withstand enormous loads and environmental stresses. Structural failures here can be catastrophic.

Maintaining this equipment in the Gulf Coast’s harsh environment presents unique challenges. Factors such as saltwater corrosion, extreme weather events, and the constant vibration and stress of drilling operations all contribute to accelerated wear and tear. The difference between a well-maintained rig and a neglected one can often be measured in lives saved or lost.

The Impact of Equipment Failures on Worker Safety

Recent industry reports indicate a troubling uptick in equipment-related injuries on Gulf Coast drilling rigs over the past five years. These incidents range from minor injuries caused by malfunctioning hand tools to life-altering accidents resulting from major equipment failures.

The consequences of these incidents extend far beyond immediate medical expenses:

- Lost productivity and operational downtime

- Increased insurance premiums

- Legal expenses and potential settlements

- Damage to company reputation

- Long-term healthcare costs for injured workers

For Gulf Coast communities like Mobile, where the oil and gas industry is a major employer, these incidents have ripple effects that touch every aspect of local life.

Regulatory Framework and Industry Standards

In response to growing concerns over equipment-related injuries, both federal regulators and industry bodies have strengthened their oversight and guidelines. OSHA has implemented specific regulations for drilling rig equipment, emphasizing:

- Regular equipment inspections

- Proper maintenance documentation

- Worker training on equipment operation and safety protocols

However, regulations alone aren’t sufficient. The most successful Gulf Coast drilling operations implement comprehensive safety management systems that exceed basic compliance. These typically include:

- Rigorous preventive maintenance schedules

- Advanced risk assessment protocols

- Continuous improvement processes based on incident data analysis

Industry leaders in the region are also adopting best practices that prioritize equipment reliability:

- Implementing reliability-centered maintenance (RCM) programs

- Utilizing root cause analysis for all equipment failures, no matter how minor

- Fostering a culture of safety where workers are encouraged to report potential issues without fear of reprisal

The Role of Training and Safety Culture

While advanced technologies play a crucial role, human factors remain paramount in preventing equipment-related injuries. Gulf Coast drilling operations are focusing on comprehensive training programs covering:

- Proper equipment operation and maintenance procedures

- Recognition of potential equipment failures

- Emergency response protocols

Moreover, leading companies are addressing the impact of fatigue and work schedules on equipment operation. Long shifts and high-stress environments can lead to errors in judgment that compromise safety. Implementing balanced work rotations and stress management programs is becoming standard practice in the industry.

Creating a culture of safety and accountability is perhaps the most critical step. This involves:

- Encouraging open communication about safety concerns

- Recognizing and rewarding proactive safety behaviors

- Ensuring that safety considerations always trump production pressures

Emerging Technologies in Rig Safety

The Gulf Coast’s drilling industry is at the forefront of adopting new technologies to enhance rig safety:

- Remote monitoring systems allow experts to keep an eye on critical equipment from onshore control centers, providing an additional layer of oversight.

- Machine learning algorithms are being employed to analyze vast amounts of operational data, identifying patterns that might indicate impending equipment failure.

- Automation of high-risk tasks is reducing the need for human intervention in dangerous situations, significantly lowering the risk of injuries.

Don’t Face Equipment-Related Injuries Alone: Fuquay Law Firm Is Here to Help

If you or a loved one has been affected by an equipment-related injury on a drilling rig along the Gulf Coast, know that you are not alone. At Fuquay Law Firm, we have in-depth experience with maritime accident cases. We understand the complexities of these incidents and the profound impact they can have on workers and their families. Our experienced team is ready to stand by your side, fight for your rights, and help you navigate the challenging legal landscape of workplace injuries in the oil and gas industry.

Call us at 251-473-4443 or reach out through our website to set up a free, no-obligation consultation. Your path to justice and recovery starts here.